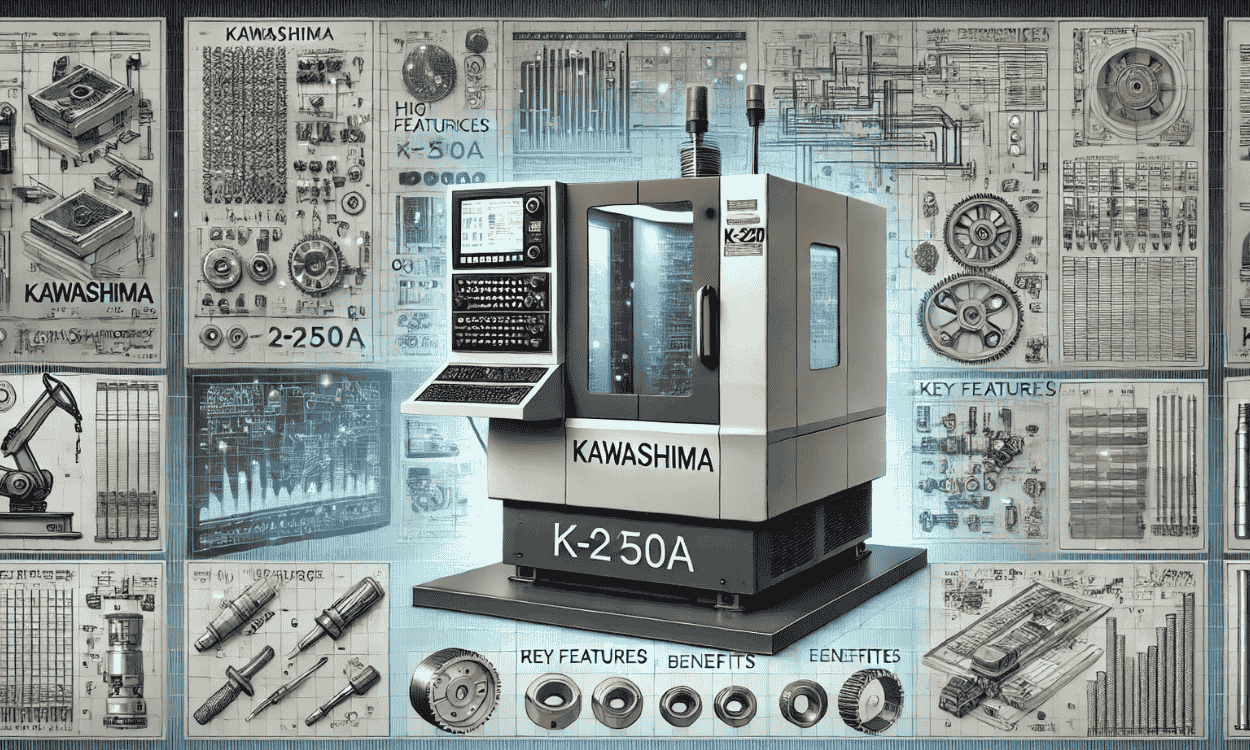

The Kawashima K2-250A is an advanced and reliable industrial equipment that is specifically made to handle challenging tasks in a variety of industries, such as landscaping, agricultural, and construction. Constructed from sturdy, premium materials, it performs exceptionally well under demanding operating conditions, minimizing wear and tear and maintenance requirements. It is an environmentally aware option for companies because of its cutting-edge engine technology, which produces strong, fuel-efficient performance while reducing emissions to satisfy contemporary environmental criteria.

With its outstanding productivity design, the K2-250A supports both small- and large-scale projects by effectively managing hard jobs like digging, hauling, and heavy lifting. Operators of all skill levels may efficiently use the machine thanks to its intuitive controls. Its capacity for concurrent operation and maintenance, which reduces downtime and maintains efficient workflows, is a noteworthy benefit.

In terms of cost-effectiveness, the K2-250A’s low fuel consumption and low maintenance needs provide significant long-term savings and a good return on investment, despite the original investment potentially being substantial. Compatibility with a variety of accessories increases the machine’s adaptability for a broad range of industrial settings and applications. A safe working environment is guaranteed by safety elements such protective guards, ergonomic controls, emergency stop systems, and good operator sight.

Durable and Rugged Build: Designed for Tough Jobs

The Kawashima K2-250A is well known for its robust and long-lasting construction, which was intentionally designed to withstand the rigors of demanding industrial tasks. This machine is made of sturdy, high-quality materials and is intended to endure the challenging working conditions frequently seen in industries like landscaping, agriculture, and construction. Its durable design and strengthened parts reduce deterioration, increasing longevity and lowering maintenance requirements.

Significant advantages result from this resilience, particularly in vital businesses where interruption might cause expensive delays. Because of the sturdy design, fewer repairs are needed, which eventually lowers long-term maintenance expenses for both enterprises and operators. Additionally, the Kawashima K2-250A’s resilience in harsh, demanding conditions gives experts confidence that their equipment will operate reliably and without sacrificing quality.

The Kawashima K2-250A is a reliable workhorse on any demanding job site since it is designed to not only last but also operate at peak efficiency for lengthy periods of time. Professionals who need dependable, high-performance gear choose it because of its endurance, cutting-edge technological features, and easy maintenance access.

Also Read More: Chalipure Pins

Cutting-Edge Engine Technology for Efficiency and Power

Modern engine technology in the Kawashima K2-250A is intended to provide power and efficiency in demanding industrial settings. Even when faced with demanding tasks, the machine can function at its best thanks to this sophisticated engine’s powerful and reliable output. Because of its fuel-efficient design, consumers can save money on operational expenses while still getting reliable performance.

Furthermore, the Kawashima K2-250A engine is designed with pollution reduction technologies that enable it to satisfy contemporary environmental regulations. Businesses looking to strike a balance between sustainability and productivity are finding that this eco-friendly strategy is more and more crucial.

Exceptional Productivity Across Multiple Applications

Professionals in fields including construction, agriculture, and landscaping use the Kawashima K2-250A because of its outstanding output in a variety of applications. This equipment is designed to efficiently perform a wide range of difficult jobs, such as heavy lifting, hauling, and excavating. Its strong engine enables it to continue operating at optimum efficiency even for prolonged periods of time, guaranteeing that projects move forward without needless delays.

The K2-250A is valued by experts for its reliable performance in both small and large-scale projects. Businesses handling a variety of tasks will particularly benefit from its adaptability and strong output, which allow it to adjust to changing operational demands without compromising efficiency.

Additionally, teams may collaborate more easily and productively thanks to the controls’ ease of use, which are made for users of various skill levels. Additionally, the machine’s design allows for simultaneous repair and operation, reducing downtime and maintaining uninterrupted processes.

Step-by-Step Guide to Operating and Maintaining the Kawashima K2-250A

Professionals in fields including construction, agriculture, and landscaping use the Kawashima K2-250A because of its outstanding output in a variety of applications. This equipment is designed to efficiently perform a wide range of difficult jobs, such as heavy lifting, hauling, and excavating. Its strong engine enables it to continue operating at optimum efficiency even for prolonged periods of time, guaranteeing that projects move forward without needless delays.

The K2-250A is valued by experts for its reliable performance in both small and large-scale projects. Businesses handling a variety of tasks will particularly benefit from its adaptability and strong output, which allow it to adjust to changing operational demands without compromising efficiency.

Additionally, teams may collaborate more easily and productively thanks to the controls’ ease of use, which are made for users of various skill levels. Additionally, the machine’s design allows for simultaneous repair and operation, reducing downtime and maintaining uninterrupted processes.

Cost-Effectiveness: Long-Term Savings with the Kawashima K2-250A

Efficiency in the Kawashima K2-250A’s operation and maintenance guarantees optimal output, robustness, and security. This comprehensive, simple-to-follow tutorial will help you make the most of your machine:

- Step 1: Pre-Operation Inspection

Do a thorough inspection first thing in the morning. Verify all of the machine’s vital parts, such as the fuel and hydraulic fluid levels, tire pressure, and general condition. Check for any obvious leaks or damage. - Step 2: Starting the Machine

Start the engine with the ergonomic control panel. Make sure the machine’s surroundings are clear and that safety features like the emergency stop are operating. Control is improved and operator fatigue is decreased by the user-friendly design. - Step 3: Selecting and Attaching Implements

Select the right attachment for the job at hand, such as lifting equipment or buckets for digging. A wide variety of attachments are compatible with the Kawashima K2-250A, which may be easily switched out to accommodate various tasks. - Step 4: Operating the Machine

Operate the controls effortlessly, making use of the high-torque engine to complete heavy-duty chores efficiently. Observe safety procedures and maintain open lines of contact with any coworkers in the vicinity. - Step 5: Routine Maintenance During Operation

This machine’s ability to operate and maintain itself simultaneously is one of its main features. Quick checks, such as checking filters, tightening loose parts, and keeping an eye on fluid levels, can be done while the machine is operating without interfering with your job. - Step 6: Post-Operation Care

After finishing your task, safely shut off the computer. To stop wear, clean moving parts of dirt and debris. Look closely for any indications of wear or damage that need to be fixed. - Step 7: Scheduled Servicing

Follow the manufacturer’s recommended maintenance schedule, which should include routine mechanical checks, oil changes, and filter replacements. Regular maintenance prolongs the life of machines and averts expensive malfunctions.

Versatility and Customization

A vital asset in a variety of industries, including landscaping, agriculture, and construction, the Kawashima K2-250A stands out for its remarkable versatility and customizable options. Because of its multifunctional design, this machine can be used in a variety of settings and to meet the needs of various projects.

One of the main reasons for its adaptability is that it works with a variety of attachments that are simple to switch out to fit different jobs. Users can equip the machine with various equipment to optimize productivity and operating efficiency, whether the task involves heavy lifting, material hauling, or soil preparation.

Additionally, operators can easily traverse difficult sites because to its compact design, which improves mobility in confined spaces without compromising power. This flexibility helps firms minimize the need for numerous specialized machines and optimize resource utilization, in addition to increasing job site efficiency.

Commitment to Environmental Sustainability

Because of its strong dedication to environmental sustainability, the Kawashima K2-250A is a great option for businesses trying to strike a compromise between eco-friendly practices and productivity. Its cutting-edge engine technology is specifically designed to lower pollutants, assisting the machine in meeting the most recent and strict environmental regulations. In addition to lowering the carbon footprint, this emission reduction helps companies that want to make environmental awareness a part of their company culture.

Additionally, the machine’s design prioritizes fuel efficiency, which reduces running expenses and, by using less fuel, lessens its impact on the environment. Professionals in landscaping, agriculture, and construction gain from this sustainable strategy without compromising performance or power.

The Kawashima K2-250A’s green credentials are further enhanced by the materials chosen for its construction, which are long-lasting and sustainable. The Kawashima K2-250A is a powerful and environmentally conscious investment since it allows businesses to retain high operational efficiency while practicing responsible environmental stewardship.

Safety Features: Protecting Operators and Worksites

The Kawashima K2-250A is a reliable machine in tough industrial settings because it places a high priority on safety elements to safeguard workers and work areas. One of its primary safety features is an emergency stop system, which enables the machine to be instantly turned off in the event of a serious emergency, averting mishaps before they get out of hand.

Strong guards and shields are built into the machine to reduce exposure to moving parts and lower the possibility of accidents while it is in use. In addition to increasing operator comfort, its ergonomic controls lessen vibration fatigue, which is crucial for staying focused during extended workdays.

When paired with efficient lighting solutions, improved visibility from the operator’s station guarantees a greater awareness of the surroundings, which enhances safety in low light. All things considered, these well-considered safety measures show Kawashima’s dedication to a safe workplace where employees can carry out their responsibilities effectively without putting themselves or others in risk.

Real User Stories: The Impact of the Kawashima K2-250A

Thanks to its strength, durability, and adaptability, the Kawashima K2-250A has made a big impression on its users in a variety of industries. For example, construction foreman John attributes significant improvements in project turnaround times to this machine. Even on rocky, uneven terrain, where other equipment frequently failed, he has depended on its sturdy build to function effectively.

Overseeing a sizable landscaping job, Sarah discovered that her crew was able to concentrate more on project objectives due to the K2-250A’s robust construction and ease of maintenance than on ongoing machine repairs. This dependability kept her project on track and decreased downtime.

Despite his lack of prior expertise, Mike, a novice in operating construction equipment, valued the machine’s user-friendly controls, which enabled him to become proficient quickly and work with assurance.

FAQs

What industries is the Kawashima K2-250A best suited for?

The machine is perfect for applications requiring strong performance and adaptability, such as landscaping, agriculture, and construction.

How fuel-efficient is the Kawashima K2-250A?

Its cutting-edge, fuel-efficient engine lowers emissions and fuel consumption, making it economical and ecologically beneficial.

Can the Kawashima K2-250A operate with different attachments?

Indeed, it enhances versatility on job sites by supporting a large variety of customized attachments for different jobs.

What safety features does the K2-250A include?

Protective guards, ergonomic controls, an emergency stop system, and improved operator sight are examples of safety features.

Is maintenance difficult?

No, the machine’s easy-to-reach components allow for regular maintenance and repairs with little downtime.

Conclusion

One notable example of a reliable, adaptable, and environmentally friendly industrial equipment designed for demanding applications in landscaping, agriculture, and construction is the Kawashima K2-250A. Its sturdy construction and state-of-the-art engine technology guarantee strong but fuel-efficient performance. The machine is a wise investment that provides dependable performance and long-term savings because of its adaptability through interchangeable attachments, extensive safety measures, and easy maintenance design. The Kawashima K2-250A is a great option for professionals looking for productivity without sacrificing ease of use, as demonstrated by real user experiences.

Also Read More: Meggerz Xmeg